- Home

- Industries

- Pharmaceutical

- Small Molecule

- Continuous Flow Reactors

Continuous Flow Reactors

Low Volume, High Value

Novel Continuous Reactors represent the next stage of manufacturing evolution, but bring a unique set of challenges.

Very short residence times test the limits of PAT instrumentation. High turn-down rates present a very broad range of 'normal' operating conditions. High feedstock costs impose limits on development and testing runs. The units are designed to run multiple different products, sometimes in multiple lots.

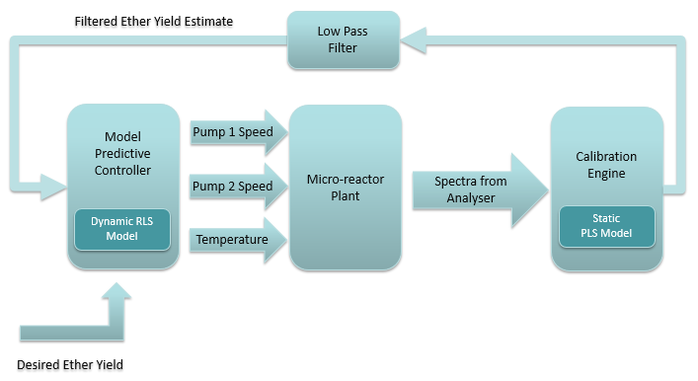

Working with the Centre for Process Innovation (CPI), in a project co-sponsored by AstraZeneca, Perceptive Engineering developed the tools needed to fully exploit micro-reactors. Using results from off-line HPLC analysis and on-line MIR instrumentation, Perceptive produced a real-time estimate of product yield. This 'soft' sensor enabled control to be exercised more tightly, reducing testing time and providing a near-instant measurement of product quality.

Click the schematic below to download the case-study. Or visit this News Update to read about a new platform being developed by Perceptive.