- Home

- Industries

- Nutritionals and Ingredients

Nutritionals and Ingredients

We help blue-chip companies increase the capacity of their existing assets, by operating their plants closer to constraints, improving yield and increasing throughput.

Rising energy costs, higher prices for raw materials, and more demanding end users have pushed efficiency and quality to the top of the agenda. Capital expansion can be a costly and disruptive route to increasing production capacity, which is why world-class manufacturers are finding answers elsewhere.

Our Advanced Process Control solutions have been chosen by some of the world's biggest dairy producers, because it delivers rapid payback with minimum disruption or cost. Typical return on investment is 3-6 months on yield and throughput alone, but APC offers a host of other process performance benefits.

|

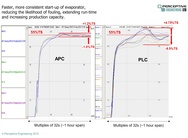

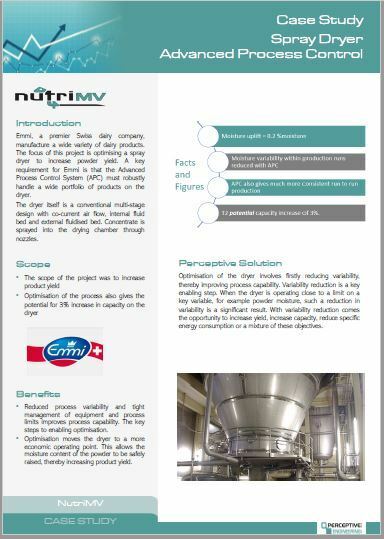

Case Study - Spray Dryer Optimisation

Click on the image to download the case study on increasing yields of dairy powders through spray dryer optimisation

To explore our full range of process industry solutions visit Smart Process Development Smart Process Smart Maintenance Smart Scheduling