- Home

- Industries

- Chemical and Formulated

Chemicals, Formulated and

Personal Care Products

High-value formulated products are often produced from the 'actives' which deliver specific benefits, along with a complex selection of other ingredients that convey other desired properties, such as texture, appearance, shelf-life, miscibility, or odour. The manufacture of these products represents a series of challenges:

how to ensure homogeneous distribution of the 'active' components in the finished product

how to ensure targets for quality and products are consistently met

how to manufacture the product in a cost-effective way, taking into account blending and reaction times, product testing, machine cleaning

Ongoing research is yielding new techniques and understanding, about how physical properties are affected and influenced by the process and how it is operated, monitored and controlled.

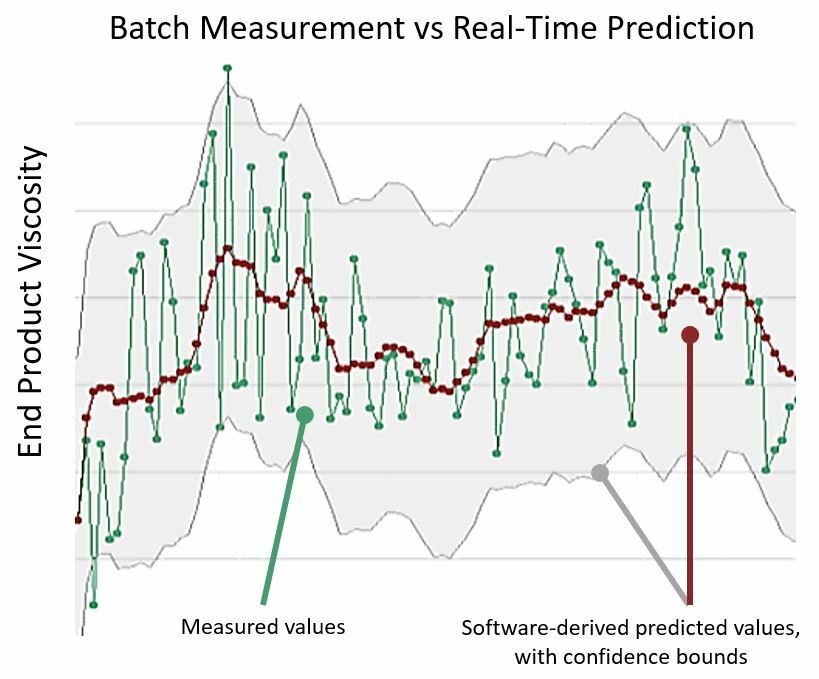

Analysing this data and turning it into a reliable methodology for process optimisation is where Perceptive comes in. The PerceptiveAPC platform enables end-product quality to be predicted with high levels of confidence, no matter how variable the quality of raw ingredients. In turn, this allows manufacturers to shorten cycle times and gain significant capacity from their existing assets.

Project CL4IR

The Centre for Process Innovation (CPI) recently developed a physical rig to enable understanding of the process scale-up of complex liquid products. The key aims of Project CL4IR are:

Facilitate rapid learning of how formulated product properties discovered at the lab scale can be manufactured economically and flexibly.

Understand the dynamics of manufacturing formulations at different scales and enable predictive scale-up of batch formulation processes.

Develop, validate and utilise new sensor technologies and process analytics technologies

Develop automated process monitoring and control schemes.

Perceptive's software was selected as the automation platform for Project CL4IR, combining data capture from PAT devices, data analytics, process modelling, robust predictive control, and inference of finished product properties.

Manufacturers will be able to adjust process operation in real time to optimise quality, increase throughput, narrow specification tolerances and reduce off-specification product.

To learn more, please download Perceptive's data sheet or CPI's project summary.

Continuous flow reactors represent the next generation of high-value, low volume manufacturing assets.

To explore our full range of process industry solutions visit Smart Process Development Smart Process Smart Maintenance Smart Scheduling