- Home

- Industries

- Pharmaceutical

- Small Molecule

- Hot Melt Extrusion

Hot Melt Extrusion optimised with Machine Learning

Hot Melt Extrusion (HME) is an emerging technology for the continuous manufacture of pharmaceutical drugs across a wide range of dosage forms, include solid dose formulations which are particularly useful for poorly soluble APIs. HME facilitates the Quality by Design (QbD) approach to pharmaceutical manufacturing through the integration of inline PAT tools for advanced process monitoring and control.

Perceptive Engineering, in collaboration with its university and industrial partners, has developed and implemented two solutions that use real-time PAT integration, Design of Experiment (DoE), multi-variate statistical process control (SPC) tools and machine learning to monitor and optimise the pharmaceutical HME process.

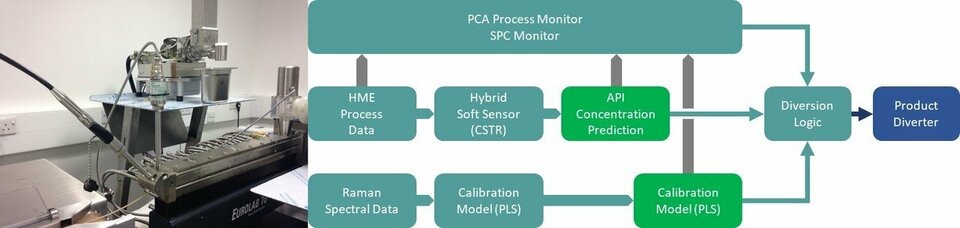

HME process monitoring and fault detection solution uses Critical Quality Attribute (CQA) predictions from two independent sources: a hybrid soft sensor and a RAMAN-based calibration model. These enable the detection of common process faults, such as material impurities or degradation, feeding issues and equipment faults.

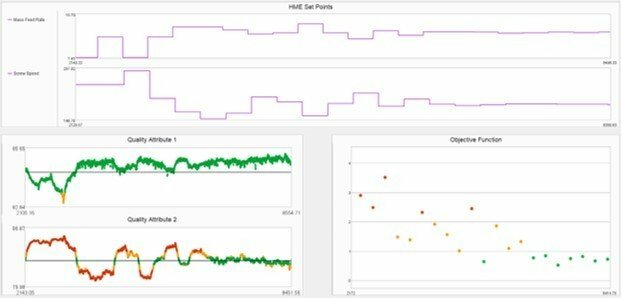

Perceptive's HME optimisation solution employs a machine learning algorithm that manipulates the mass feed rate and screw speed in real-time to drive two CQA - derived by spectral analysis of the extrudate colour and transparency - to their optimal targets.

The real-time HME process monitoring scheme is flexible and can be applied to a wide range of excipients and APIs to reduce the out-of-specification product and thereby facilitate the downstream processing of the extrudate.

Learn more