- Home

- Industries

- Recycled Fibre Plant

De-Inking Plant: Process Optimisation and Quality Control

Case Study

Recycled Fibre

Company

Aylesford Newsprint Limited

Challenge

Improve quality, reduce production costs

Solution

De-Inking Plant Optimisation

Results

Payback within 3-6 months

BUSINESS CHALLENGE

Aylesford Newsprint Limited manufactured a range of 100% recycled newsprint under the "Renaissance" brand. The Aylesford site in the south-east of England operated two paper machines; PM13 and PM14 to produce an average of 400,000 tonnes of recycled newsprint every year.

The De-Inking Plant converts post consumer paper into a pulp for use on the Paper Machines. For newsprint grades the process typically consists of a series of pulping, cleaning, screening, ink-flotation, bleaching and thickening stages.

The business challenge is to supply sufficient quantities of pulp to the paper machines at the lowest economic price possible whilst meeting all quality specifications.

SOLUTION

Operator can select optimisation targets on the fly - lower chemical costs, higher yield, increased production rate - to suit production and customer demands. Read more...

PERCEPTIVE SOLUTION

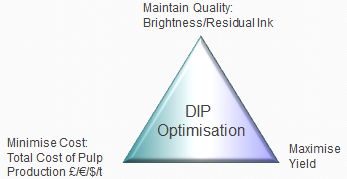

De-Inking Plants are required to produce pulp that conforms to multiple quality specifications such as brightness, residual ink or ash while the total cost of pulp production is minimised. Simultaneously, the process must be controlled within a window defined by equipment design constraints and bottlenecks to ensure safe and efficient operation.

Perceptive have delivered an Advanced Process Control system on Aylesford's De-Inking Plant which comprises; multiple Model Predictive Controllers (MPC), a Data Quality Monitor and a yield optimiser. The system provides coordinated control of product quality, production rate and process constraints by adjusting key stock flows, consistencies, flotation cell levels and bleaching variables. An interface is provided on the DCS which allows Aylesford production staff to enter the current costs of recyclable fibre and bleaching chemicals. The optimiser uses these costs to balance flotation yield against bleach consumption to minimise overall cost of pulp production.

RETURN ON INVESTMENT

The first deliverables of the solution are a series of Model Predictive Controllers. The controllers provide:

- Closed loop control pulp brightness and residual ink. The variability in these quality parameters has reduced by 60% and 40%, respectively.

- Control of flotation stock flows, cell levels, production rate and the bleaching process.

- Improved plant agility; production rate can be adjusted automatically to balance throughput to machine demand or to setpoint and pulp quality is maintained within specification during large production changes.

- Constraint control of key plant variables such as tank levels, disk filter speeds and cleaner pressures.

- Control of the Dissolved Air Flotation units, reducing outlet solids variation by 60%.

The platform of reduced variability delivered by the MPCs has been used as a basis for process optimisation. The yield optimiser delivers the following primary business benefits:

- Consumption of bleaching and flotation chemicals has reduced by 20-25%.

- Yield has improved by 2-3%.

The benefits delivered a full return on investment within 3 months of commissioning, sustained via an ongoing support program provided by Perceptive.

"The PerceptiveAPC system installed on our process has provided significant improvements in quality and process stability. The system has reduced the standard deviation of final brightness by 60% while optimising production rate, chemical dosages and yield in real-time. We also continuously develop the system to give further improvements in the control of our product. This allows us to deliver pulp of a more consistent quality at any production rate and at the lowest possible total cost to our customers."Jo Mills, Aylesford FPP Production Manager. |