- Home

- Our Software

- WaterMV

WaterMV

Suppliers of drinking water and those processing wastewater are facing ever-tougher prospects in the years ahead. Processing of water requires energy, to pump, filter, aerate, distribute or discharge. Standards of water quality are increasing, to protect health and the wider environment.

Meeting these regulations could necessitate increased energy or chemical use, as well as capital expenditure on process upgrades. Tighter discharge constraints, coupled with population expansion and a changing climate, exert added pressure on existing processing plants.

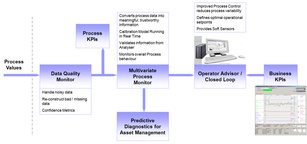

Improved Asset Management with Advanced Process Control - WaterMV

Advanced Process Control has been implemented in a broad range of manufacturing industries for over twenty years, to continually drive the process towards optimum operation. Perceptive Engineering have successfully transferred that expertise and those benefits to the water industry.

Modelling your process - using data you're already collecting - helps uncover every opportunity to reduce energy or improve quality, by identifying, managing and reducing the variability in your process.

By determining the theoretical capability of each plant, then understanding the measures needed to achieve and maintain that capability, asset efficiency is increased, asset performance is optimised.

More efficient operation results in lower energy requirements and can significantly extend asset life; capital expansion of the plant can be deferred, even with a growing user population.

Click the image below to learn more, or read about our solutions.

|

|

|

Data Rich, Information Poor - From Monitoring to Managing to Optimising

The water industry is becoming more automated and reliant on data from remote sensors. Effective management and operation of water assets does not rely on the amount of data generated, but rather on the quality, reliability and interpretation of that data. Operators and managers need tools to turn process metrics into process knowledge, to help support decisions critical to the operation.

Perceptive Engineering has pioneered software to test and validate the integrity of process data. This software has long been utilised in food processing, steel making and the pharmaceutical sector. It has been developed to form part of a decision support system for the water industry.

WaterMV provides plant-wide asset management in real-time, by validating all critical data reaching the control room and highlighting signal abnormalities or process faults. Plant operation becomes more reliable and robust; assets can be run closer to their design constraints; capacity can be increased without capital expansion.

Perceptive Engineering is working in partnership with the largest water utility companies in the UK and Netherlands, to deliver improved asset utilisation in potable and waste water treatment.