- Home

- Industries

- Pharmaceutical

- Software

- PharmaMV Real Time

Unlocking the benefits of PAT and QbD

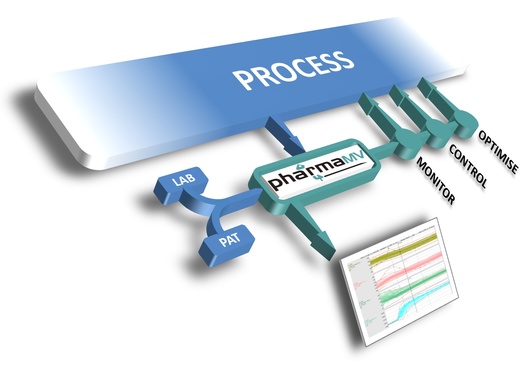

Take the next steps in monitoring, control and optimisation of your pharmaceutical manufacturing process, using the same software platform you used for development. With no new tools to learn, this means faster time from lab to pilot plant to full-scale production.

Perceptive Engineering's pharmaMV provides leading-edge multivariate analysis tools, real-time pharmaceutical process control, and a host of process monitoring and verification capabilities, all within one suite.

Users can integrate PAT instrumentation directly into the same platform that captures and aligns other process and quality data. Current and predicted performance can be visualised and shared with secure, user-configurable dashboards.

Achieve or exceed your business KPIs by increasing process throughput, increasing yield, reducing rejects, reducing cost of quality. Enhance process knowledge and understanding. Enable continuous process verification and shorten time to market.