- Home

- Industries

- Pharmaceutical

- Pharma Solutions

- Advanced Process Control Batch and Continuous

Predictive, Optimised Control of Batch and Continuous Processes

Advanced Process Control for Pharmaceutical Manufacturing

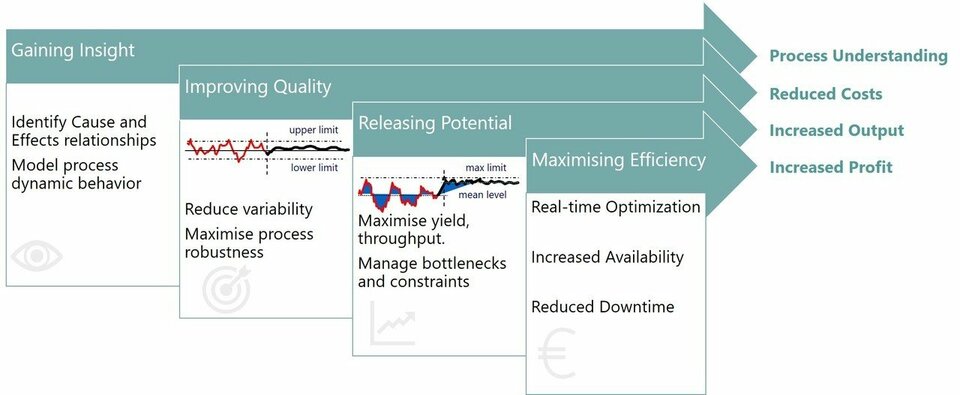

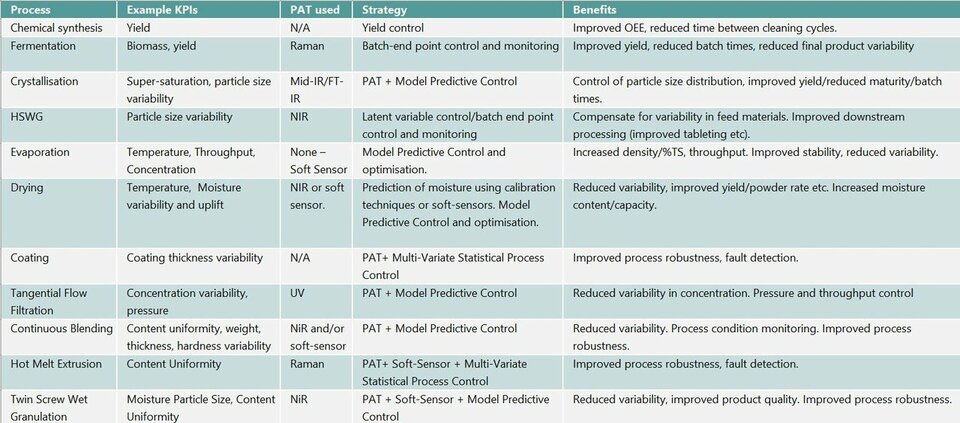

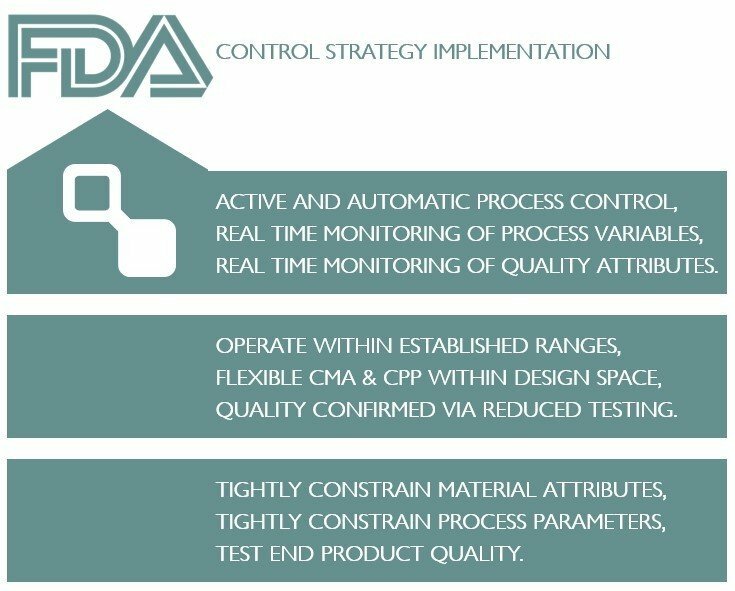

Advanced Process Control (APC) describes a set of tools used in process industries that are far more sophisticated than basic control strategies, such as PID control. Model Predictive Control (MPC) is a well-proven APC technique widely used in many process industries that is now delivering significant benefits within the pharmaceutical sector. This has a proven track record of delivering improved product quality, higher yield, greater agility and tangible savings in time, cost and energy.

In 'standard' pharmaceutical control, variability from raw materials - and the process itself - is passed directly through to the product, affecting yield, throughput and final quality. APC does not replace this 'standard' pharmaceutical control; rather, it is the next evolutionary step, combining process responses with offline and online quality measurement, to deliver true optimisation.

Furthermore, APC enables and supports new technologies such as continuous manufacturing, real-time release, micro-factories and customized medicines.

How does it work?

MPC simultaneously controls and optimises process operation in real-time:

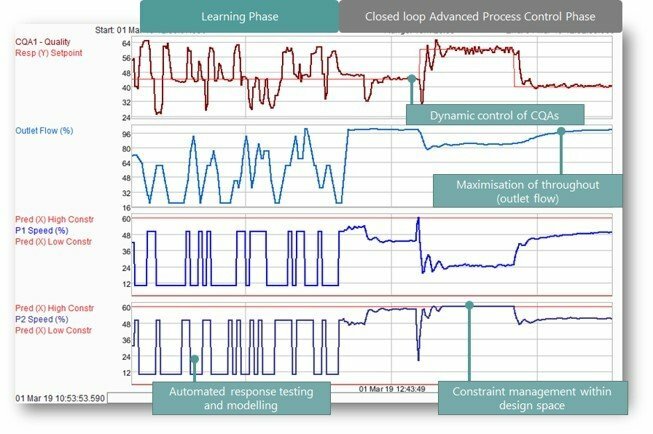

Model

A dynamic multi-variable model is built that describes the relationships between Critical Process Parameters (CPP) and Critical Quality Attributes (CQAs). PharmaMV supports Pharma 4.0 techniques such as the use of mechanistic Digital Twins, Machine Learning and automated modelling to streamline model development and maintenance

Predictive

The model is used to predict future behaviour of the process including the impact of known disturbances such as raw material variability (CMAs). The controller continuously monitors the model performance in real-time.

Control

At regular intervals, the controller calculates an optimal set of coordinated adjustments to multiple CPPs in order to control the process Critical Quality Parameters. It exploits all opportunities to maximise product quality and process robustness. It stabilises the production process by compensating for disturbances using the model’s predictions and feedback.