- Home

- Industries

- Pharmaceutical

- Small Molecule

- Crystallisation

Improved Control of Particle Size and Product Characteristics

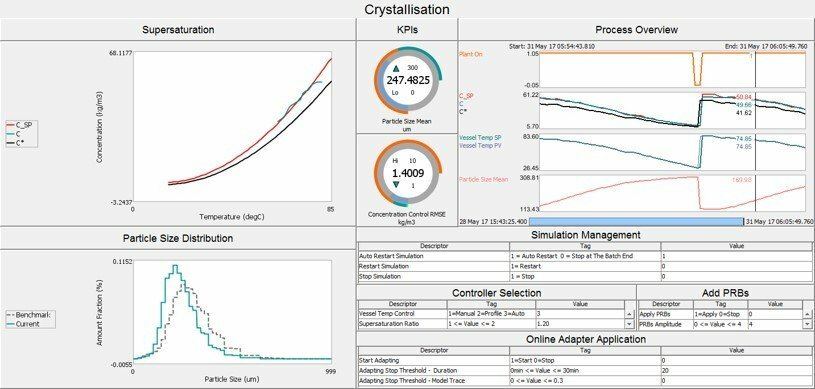

Batch Crystallisation

New techniques for 'golden batch' identification, trajectory control and end-point prediction deliver more consistent quality, faster turnaround and less waste. Traditional control often uses fixed recipes and cool-down profiles, with little or no integration of data from PAT devices. Result: lower yield, high variability in particle size. Perceptive's PharmaMV platform addresses all these issues.

- Data validity, instrument integrity determined and reported in real time

- PAT calibration models developed directly within the software

- Tighter control by using a digital model of process behaviour

- Critical Quality Attributes can be inferred in real time

Click the image to learn more

Continuous Crystallisation

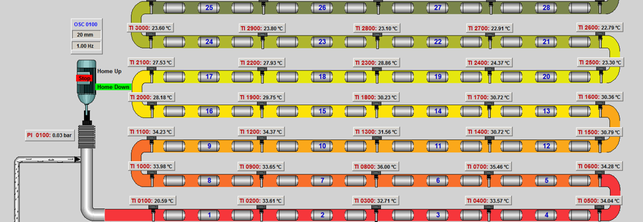

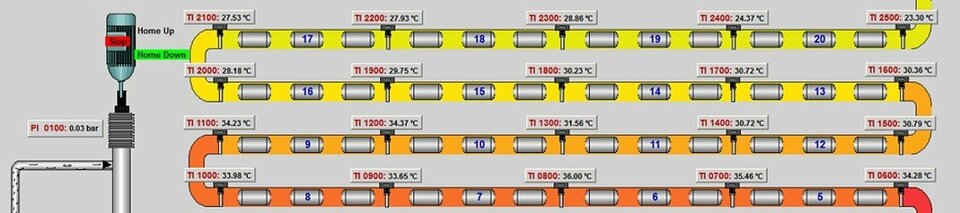

The new breed of continuous oscillatory baffled reactors - such as the Cambridge Reactors 'Rattlesnake' and Nitech's DHN10 or DN15 units - promises a new way of thinking. Mixing is uniform and without shear; heat can be transferred rapidly even during plug flow; and the units are scalable by design. But these units pose the same challenges as in batch production: raw material quality is variable, which impacts final product quality, yield, waste and cost of manufacture.

The tools and techniques to solve this dilemma are already embedded within Perceptive's

PharmaMV platform. Individual, but closely-linked, Model Predictive Controllers were developed:

Temperature Profile: maintained at an optimum throughout the process unit

Super-Saturation: continuous adjustment of seed loading, based on concentrations derived from FTIR data

Particle Size: continuous adjustment of super-saturation levels, based on FBRM results

Quality, yield and throughput can all be optimised. Particle size distribution spread can be reduced by 30-60%

Click the image to learn more